ITS Lecturer Designs Piping Complexity Solution Software

Uploaded on: October 25, 2022 9:05:32 PM 5

Jatim Newsroom-Academics of Sepuluh Nopember Institute of Technology keeps producing various innovations for the community. One of them was made by a teacher from the ITS mechanical engineering department, Nur Ikhwan ST MEng, who succeeded in developing a pump sizing simulation software.

The one often nicknamed the Ikhwan explained that the pump is one of the most used tools in industries involving liquids. Determining the right pump also requires the right calculation. “Precise calculations can be obtained using software to simulate calculations before being applied to real conditions”, he explained, Tuesday (25/10/2022).

According to Ihkwan, the existence of the software is also very important to support the learning of courses related to piping. However, in order to use the software, users have so far had to rent abroad. “The costs incurred are quite significant and can only be used on a few devices,” he said.

Based on this, the graduate lecturer from Memorial University of Newfoundland, Canada, and his team designed their own pump selection simulation software for use by students. The software can be viewed in myITS Classroom by students who need it. “Of course, with this software, there is no longer any need to pay rental fees for overseas-made software,” he said.

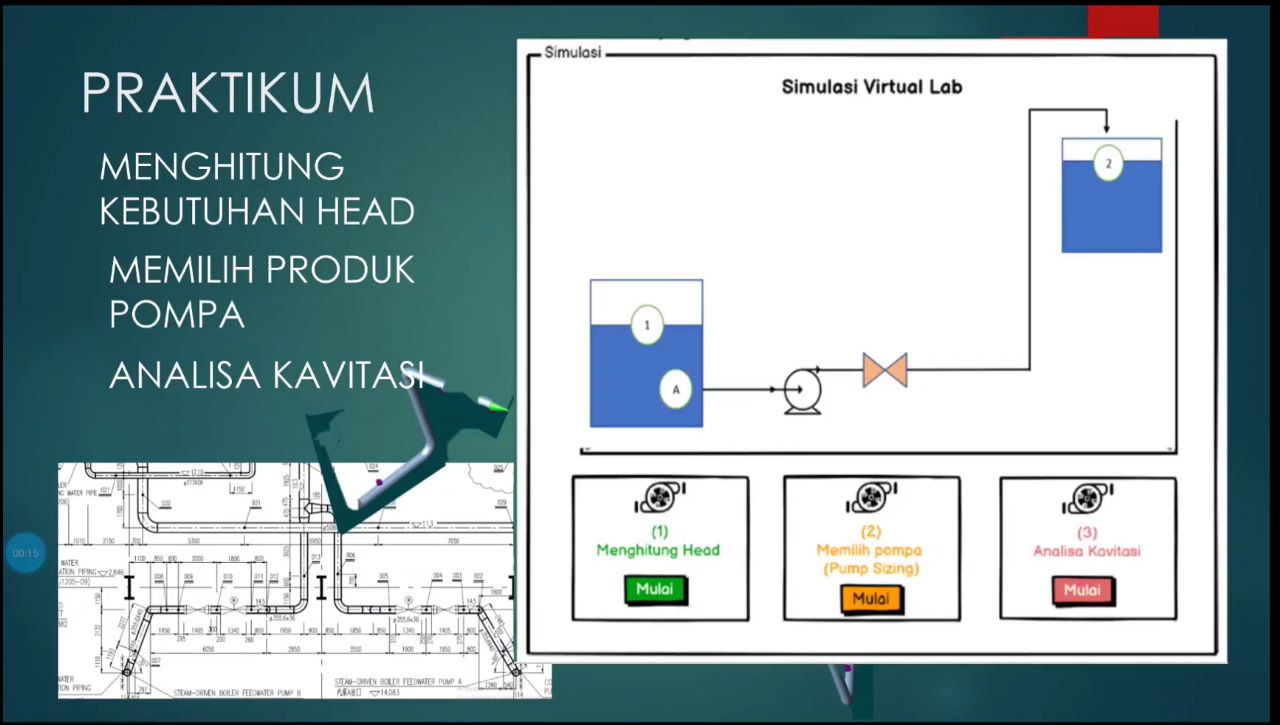

Also, explained Ikhwan, the pump selection simulation software is divided into three parts. The first part of the simulation aims to determine the head of the pump. “The pumphead itself is the energy given by the pump to the pumped liquid so that it can move from one place to another,” he explained.

In the second simulation, pump head data from the first stage along with liquid flow rate (flow) data is used to determine the correct type of pump. “It doesn’t stop there, to perfect the design of the pump that is achieved, you have to make sure that the pump is working optimally,” Ikhwan continued.

Therefore, in the third simulation, the objective is to ensure that the pump does not experience cavitation, which is the phenomenon of transformation of liquids into vapors during their flow. “This incident is indicated by the appearance of steam bubbles, vibrations and noise which can reduce performance and damage the pump,” explained Ikhwan.

He admitted that the software developed under the fluid mechanics laboratory of the ITS mechanical engineering department has been used by students since 2021. “I hope that the pump selection simulation software we have designed can help students understand the learning of piping systems analysis with easy access,” he concluded. (crazy/hjr)

“Evil pop culture fanatic. Extreme bacon geek. Food junkie. Thinker. Hipster-friendly travel nerd. Coffee buff.”